Acrylic and Polycarbonate Material Guide

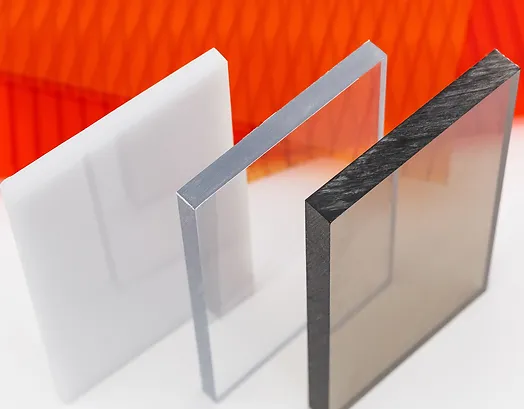

Acrylic and polycarbonate are two widely used types of clear plastic materials. Often chosen as alternatives to glass, these plastics are lightweight, durable, and shatter-resistant.

Both materials serve various purposes across industries such as construction, automotive, electronics, medical devices, signage, and consumer goods. Although they may appear similar, acrylic and polycarbonate differ in several important ways, including strength, flexibility, cost, and UV resistance.

The use of these plastics has grown steadily due to their versatility and performance in both indoor and outdoor environments. As demand increases for transparent, durable, and safe materials, acrylic and polycarbonate have become more relevant than ever.

Why This Topic Matters

Acrylic and polycarbonate materials are vital in today’s manufacturing, design, and construction sectors. As industries continue to look for lightweight, impact-resistant, and cost-effective solutions, these materials solve multiple modern challenges.

Who It Affects

Architects and designers seeking aesthetically pleasing yet durable panels and displays

Engineers and manufacturers needing strong yet light components

Healthcare professionals using clear barriers and medical equipment

Homeowners and DIYers working with safe alternatives to glass

Retailers and advertisers building displays, signs, and protective barriers

Problems Solved by Acrylic and Polycarbonate

Shatter risk reduction: Unlike glass, both materials are impact-resistant, reducing injury risk

UV protection: Polycarbonate often includes UV-blocking layers, making it ideal for outdoor use

Weight concerns: These plastics weigh less than glass, reducing shipping costs and structural load

Safety in public spaces: Clear barriers made of polycarbonate became crucial during the COVID-19 pandemic

Thermal insulation: Certain variants provide insulation properties, helping reduce energy cost

Recent Developments and Trends (2024–2025)

In the past year, several industry shifts have impacted the use of acrylic and polycarbonate:

Sustainability Focus

Recycling advancements: In 2024, new technologies emerged for recycling polycarbonate, reducing its environmental footprint.

Bioplastics innovation: Some manufacturers are blending bio-based materials with acrylic for more sustainable solutions.

Safety Standards

Improved fire-resistant polycarbonates: New grades with higher flame-retardant properties were introduced in 2025 for use in electronics and public infrastructure.

Impact-resistant acrylics: Modified acrylic formulas now offer higher durability without sacrificing clarity.

Global Market Trends

According to a 2024 report by Grand View Research, the global polycarbonate market is projected to grow at over 6% CAGR through 2030. Demand is particularly strong in the Asia-Pacific region due to infrastructure development and electronics manufacturing.

| Material | Average Impact Strength | UV Resistance | Weight (vs. Glass) |

|---|---|---|---|

| Acrylic | Moderate | High | ~50% lighter |

| Polycarbonate | Very High | High (with coating) | ~50% lighter |

Regulatory Environment

Both acrylic and polycarbonate products are subject to industry-specific standards and government regulations that govern their safety and environmental compliance.

Fire Safety and Building Codes

USA (ASTM & NFPA): Materials used in public buildings must meet ASTM E84 for surface burning and NFPA 286 for room corner tests.

EU (EN 13501): Materials must pass fire performance standards before use in construction or transportation sectors.

Environmental Regulations

RoHS (Restriction of Hazardous Substances): In the EU and several other regions, polycarbonate used in electronics must be free from lead, mercury, and other toxic materials.

REACH: The EU's REACH regulation requires full transparency regarding chemical substances used in plastic manufacturing.

Transportation and Safety

FMVSS (Federal Motor Vehicle Safety Standards) in the U.S. regulates materials used in windshields and light covers for durability and impact resistance.

Useful Tools and Resources

A variety of online tools, apps, and references can help you select and compare acrylic and polycarbonate materials:

Comparison Tools

Matmatch.com – A free material comparison platform that lets you compare physical properties of plastics.

MakeItFrom.com – Provides side-by-side comparisons of engineering materials including polycarbonate and acrylic.

Design and Fabrication Resources

Fusion 360 or SolidWorks – For engineers and product designers working with plastic components.

Plastics Handbook (Online Edition) – Offers in-depth guides to plastic properties, molding, and safety standards.

Calculators

Weight calculator (available on plastics suppliers’ websites): Estimate sheet or panel weight based on thickness and size.

UV degradation estimator: Tools like the AccuWeather UV index can help predict outdoor lifespan for uncoated plastics.

Safety and Standards Repositories

ASTM.org – Purchase or review relevant plastic standards and fire safety requirements.

UL.com (Underwriters Laboratories) – Check certification status for flame-retardant plastic grades.

Frequently Asked Questions (FAQs)

1. What is the main difference between acrylic and polycarbonate?

Answer: Acrylic is more rigid and has better optical clarity, while polycarbonate is more impact-resistant and flexible. Acrylic may crack under stress, whereas polycarbonate bends but doesn’t break easily.

2. Can I use acrylic or polycarbonate for outdoor projects?

Answer: Yes, both materials can be used outdoors. Acrylic is naturally UV-resistant and maintains clarity over time. Polycarbonate often requires a UV-protective coating to prevent yellowing and degradation.

3. Is polycarbonate stronger than acrylic?

Answer: Yes. Polycarbonate is about 250 times stronger than glass and significantly stronger than acrylic. This makes it ideal for applications like bullet-resistant windows and safety shields.

4. Can I cut and drill these materials at home?

Answer: Yes. Both materials can be cut and drilled using basic tools, but care must be taken to avoid cracking. Use fine-toothed blades and start with low speeds to prevent overheating.

5. Are acrylic and polycarbonate materials recyclable?

Answer: Yes, but recycling depends on the local facility. Polycarbonate recycling has improved recently due to better sorting technologies. Acrylic is also recyclable, but may require specific chemical recycling processes.

Summary Table: Acrylic vs. Polycarbonate

| Property | Acrylic | Polycarbonate |

|---|---|---|

| Clarity | Excellent | Very Good |

| Impact Resistance | Moderate | Excellent |

| UV Resistance | High | High (with coating) |

| Weight | ~50% less than glass | ~50% less than glass |

| Scratch Resistance | Higher | Lower |

| Flexibility | Low | High |

| Cost | Lower | Higher |

| Ease of Fabrication | Easier to cut and polish | Requires care during machining |

Conclusion

Understanding the differences and applications of acrylic and polycarbonate is essential for anyone working with clear plastic materials. Whether you're designing a product, building a structure, or selecting safety equipment, choosing the right material ensures durability, safety, and long-term performance.

By keeping up with trends, regulations, and available tools, professionals and DIYers alike can make informed decisions that balance function, cost, and sustainability.