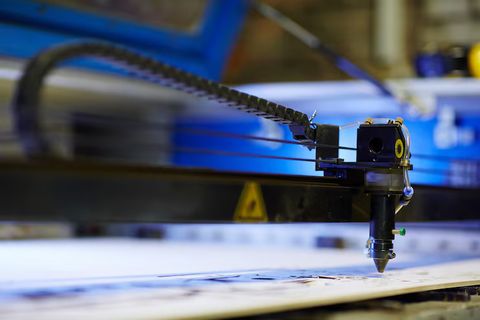

Learn CNC Laser Options: Facts and Knowledge on Fiber vs CO₂ Systems

Laser cutting has become a cornerstone of modern industrial manufacturing, offering precision, speed, and versatility. Two of the most widely used systems are Fiber Lasers and CO₂ Lasers. Both are computer-controlled machines designed to cut, engrave, or weld materials with accuracy. The choice between them depends on factors like material type, production speed, maintenance, and energy efficiency. Businesses exploring laser technology need to understand how these machines differ before making decisions for their operations.

Importance

Selecting the right laser machine is essential for industries aiming to balance cost-efficiency, accuracy, and sustainability. Fiber and CO₂ lasers solve different industrial challenges:

-

Fiber Lasers: Known for energy efficiency, high cutting speed, and suitability for metals such as stainless steel, copper, and aluminum.

-

CO₂ Lasers: Valued for versatility in cutting non-metals such as wood, glass, acrylic, and textiles.

This decision impacts not only operational costs but also compliance with environmental standards and workplace safety regulations.

Recent Updates

Several developments have reshaped the fiber vs. CO₂ laser debate:

-

2023: Fiber lasers surpassed CO₂ lasers in global sales due to improved efficiency and lower maintenance needs.

-

2024: Hybrid machines combining fiber and CO₂ technology were introduced to expand material flexibility.

-

2025: AI-powered CNC laser systems began offering real-time optimization, reducing energy use and extending machine lifespan.

These updates indicate a shift toward smart, sustainable, and flexible laser manufacturing systems.

Laws or Policies

Businesses using laser machines must follow compliance rules to protect workers and meet industry standards:

-

OSHA Regulations (USA): Require protective eyewear, ventilation systems, and laser hazard signage.

-

ANSI Z136 Standards: Provide guidance on safe laser use in research and manufacturing.

-

European Union Machinery Directive: Ensures safety requirements for laser equipment in European industries.

-

IEC 60825-1: Defines global classifications for laser safety.

-

India’s Manufacturing Safety Rules (2024 update): Encourage industries to adopt safe and energy-efficient laser systems under national industrial policy.

Tools and Resources

Businesses can rely on tools and resources to evaluate and manage CNC laser machines effectively:

-

Material Selection Databases – Help determine whether fiber or CO₂ is suitable for specific materials.

-

Energy Consumption Calculators – Estimate operational costs for each machine type.

-

CAD/CAM Software – Used to create and optimize designs for both fiber and CO₂ lasers.

-

Laser Safety Checklists – Ensure compliance with OSHA, ANSI, and IEC standards.

-

Training Platforms – Offer operator certification for handling both fiber and CO₂ systems.

Comparison Table

| Feature | Fiber Laser Machines | CO₂ Laser Machines |

|---|---|---|

| Best For | Metals (steel, copper, aluminum) | Non-metals (wood, glass, plastics, textiles) |

| Cutting Speed | Faster, especially on thin metals | Slower on metals, efficient for thicker non-metals |

| Energy Efficiency | High (lower power consumption) | Moderate (higher power consumption) |

| Maintenance | Low (solid-state design, fewer moving parts) | Higher (requires frequent servicing of optics) |

| Initial Setup | Compact and easy to integrate into smart factories | Bulkier with more complex installation |

| Lifespan | Longer (up to 100,000 hours for diode sources) | Shorter (approx. 30,000–40,000 hours) |

FAQs

Which laser is better for businesses—fiber or CO₂?

Fiber lasers are ideal for metal-intensive industries, while CO₂ lasers remain best for non-metal applications like wood, textiles, and plastics.

Are fiber lasers more expensive to maintain than CO₂ lasers?

No, fiber lasers usually require less maintenance due to fewer mechanical parts and solid-state design.

Do both fiber and CO₂ lasers require safety compliance?

Yes, OSHA, ANSI, and IEC standards apply to all types of industrial lasers, requiring protective equipment and safe work environments.

Can one machine cut both metals and non-metals?

Hybrid systems introduced in 2024 now combine fiber and CO₂ technology, making it possible to cut both efficiently.

What industries benefit most from fiber lasers?

Aerospace, automotive, medical devices, and electronics industries benefit due to the precision and speed of fiber lasers.

Conclusion

Fiber and CO₂ laser machines both play vital roles in modern industrial manufacturing. While fiber lasers dominate in speed, energy efficiency, and metal cutting, CO₂ lasers continue to serve industries requiring versatility with non-metals. With recent advancements in hybrid systems and AI integration, businesses now have more options than ever. The choice depends on production needs, materials, and compliance requirements. By understanding these factors, companies can make informed decisions that support both efficiency and workplace safety.